Introduction to flexible transformation technology of thermal power

Heating unit Steam turbine side modification technology roadmap

Heating transformation of low-pressure cylinder: it can significantly reduce the output of the unit, maintain a certain heating power, and improve the peak shaving flexibility of the unit within a certain range.

Steam turbine bypass extraction, temperature and pressure reduction and heating transformation: steam extraction from the unit bypass and heating through the temperature and pressure reducer can improve the heating capacity and peak shaving capacity of the thermal power unit to a certain extent.

High back pressure transformation of steam turbine: it can significantly improve the heating capacity of the unit and the thermal efficiency of the whole plant. However, the modified unit can only operate within a certain load range, which actually sacrifices the peak capacity of the unit.

The peak shaving technology of electric heat storage can make the unit realize "thermoelectric decoupling" - meet the demand of heating, and greatly reduce the load rate of the unit at the same time.

"Technical scheme of high voltage electrode boiler + heat storage tank"

• currently the most typical

• low investment, short construction cycle and high degree of automation

• smooth load regulation curve and fast response speed

• participate in FM technology in the future

Basic technical parameters

• voltage class: 6 – 25kV

• power output: 6 – 60MW

• hot water parameters: 0.6mpa/120 ℃

• steam parameters: 5MPa / 350 ℃

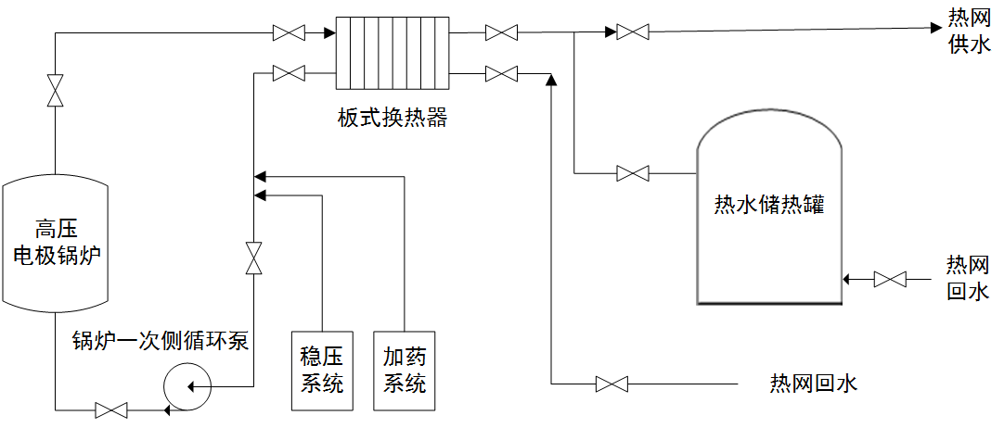

Schematic diagram of primary side and heat storage system of high voltage electrode boiler

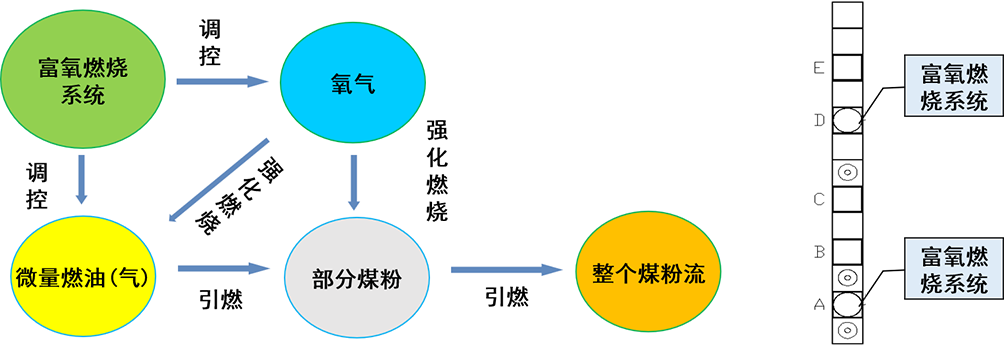

Boiler oxygen enriched combustion technology

Flexible peak shaving case application

At present, the domestic flexible peak shaving project Baoxin technology high voltage electrode boiler has a total operation performance of 62 sets, with a total operation capacity of 2116mw, including 49 sets above 50MW.

Inner Mongolia Jingke thermal power plant 10 × 12MW high voltage electrode boiler electric heat storage flexible peak shaving project

| entry name | Installed capacity | Operation time |

10×12MW | 2017 | |

State power investment Liaoning Fuxin thermal power plant 10 × 40mW flexible peak shaving project | 10×40MW | 2018 |

Huolinhe Kengkou power plant 6 × 40mW flexible reconstruction project | 6×40MW | 2018 |

State power investment Shengfa thermal power plant 2 × 40+3 × 12MW flexible peak shaving project | 2×40MW+3×12MW | 2019 |

National power investment Chifeng Xincheng thermal power plant 6 × 40mW flexible reconstruction project | 6×40MW | 2019 |

Jingneng Shengle power plant 4 × 40mW flexible reconstruction project | 4×40MW | 2019 |

State power investment Fushun thermal power branch 4 × 40mW thermal storage flexible peak shaving project | 4×40MW | 2019 |

Ningxia Zhongwei Thermal Power Co., Ltd. 6 × 40mW flexible peak shaving reconstruction project | 6×40MW | 2020 |

State power investment Inner Mongolia Daban Power Generation Co., Ltd × 40mW electric heat storage peak shaving project | 5×40MW | 2020 |

State power investment Baishan Thermal Power Co., Ltd × 40mW electric heat storage peak shaving project | 6×40MW | 2021 |